ATEX-TERRAZZO

For elimination of electrostatic charges, BARiT has developed the conductive ATEX-TERRAZZO. Some consists of water-clear epoxy resin conductive admixtures and granulates coated colourfast with polyurethane resin. A7 mm thick layer of said TERRAZZO is to be integrated.

Quick Info

- conductiv to DIN EN 1081 between 10⁴ Ω and 10⁶ Ω

- jointless, non porous

- aesthetic

- antiskid to BGR 181 R9

- mechanical stability

- chemical resistance

- decontaminatable

- almost no abrasion

- easy cleaning and disinfection

- according to ATEX directive

Optic

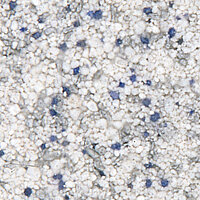

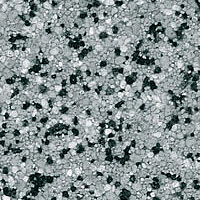

The electrically conductive BARiT ATEX TERRAZZO can be installed with blue/white, Black/gray or purple/white granules. Despite this surface's conductive additives, it maintains a bright and appealing look that is as enjoyable for a cleanroom production area just as much as in an operation room.

Due to the conductive additives, ATEX TERRAZZO has a cloudy, iridescent and metallic character to the surface.

Samples

Properties

The ATEX TERRAZZO is made of water-clear, epoxy resin and polyurethane coated colourfast granules and is installed in a layer 7 mm thick. Measured according to DIN EN 1081, the discharge resistance for ATEX TERRAZZO lies between 10⁴ Ω and 10⁶ Ω. The synthesis of both high-quality materials and a professional laying technique provides for a surface, which is equipped with good mechanical and chemical resistance.

The structure of ATEX TERRAZZO ensures high resistance to wear. For mobile operating tables or forklift traffic, the surface maintains low abrasion. Pressure strength along with impact strength for the coating is high. Application to walls as well as operating tables is dense with our any open pockets or voids.

The seamless and non-porous surface of ATEX TERRAZZO allows easy cleaning and disinfection. For this purpose we offer BARiT Cleaner, which is specifically designed to clean and care for our products. The coating does not need to be initially treated.

Datasheet| Compression strength DIN 1164** | > 40 N/mm² |

| Solid matters | 99 % |

| Bending tensile strength DIN 1164** | > 10 N/mm² |

Curing time at 20°C:

|

|

| Chemical resistance | to resistance list and self test |

| Binding agent | EP-resin |

| Easy of decontamination according to DIN 25415, Part 1 | excellent |

| Grain | BARiT card of grains |

| Grade of gloss | silk gloss or mat |

| Resistance to earth DIN EN 1081 | 10⁴ – 10⁶ Ω |

| Fillers | special granulates |

| Fire behaviour DIN EN 13501-1 | Bfl-s1, hardly inflammable |

| Consumption/m² | 2 kg/mm |

| Cleaning | BARiT Cleaner* |

| Flash point | > 100 °C |

Working under conditions of:

|

|

| Adhesive pull strength DIN EN 24624 | > 1,0 N/mm² |

| Light-fastness | conditionally good resisting to UV |

| Temperature resistance | -30 °C to +70 °C |

* according to cleaning and care instructions

ATEX TERRAZZO is a functional floor that supports the electrical conductivity. Due to application of the coating, ATEX TERRAZZO may obtain variations, accompanied by colour shadowing and shimmering. Based on the material used, it is not always possible to avoid clouding in the colour.

Any questions regarding

our BARiT Clean Room Floors?

Just call us or send us an email.

+49 711 939291-0 info@no-spam-pleasebarit.deAs an alternative you can use our contact form to get in touch with us:

go to our contact form