MASTERTERRAZZO and jointless BARIT Kitchen Floor at GE ADDITIVE 3D Campus Campus Lichtenfels

| product category | BARiT Commercial Kitchens, BARIT Designer Floors |

| floortype | KITCHEN FLOOR R9 MUSEUM TERRAZZO, MUSEUMS-TERRAZZO |

| area size (m²) | ca. 555 m² Kitchenfloor & Terrazzo |

| architect | Schmelzle+Partner mbB Architekten BDA |

| client | GE Additive |

| build year | 2020 |

floor description:

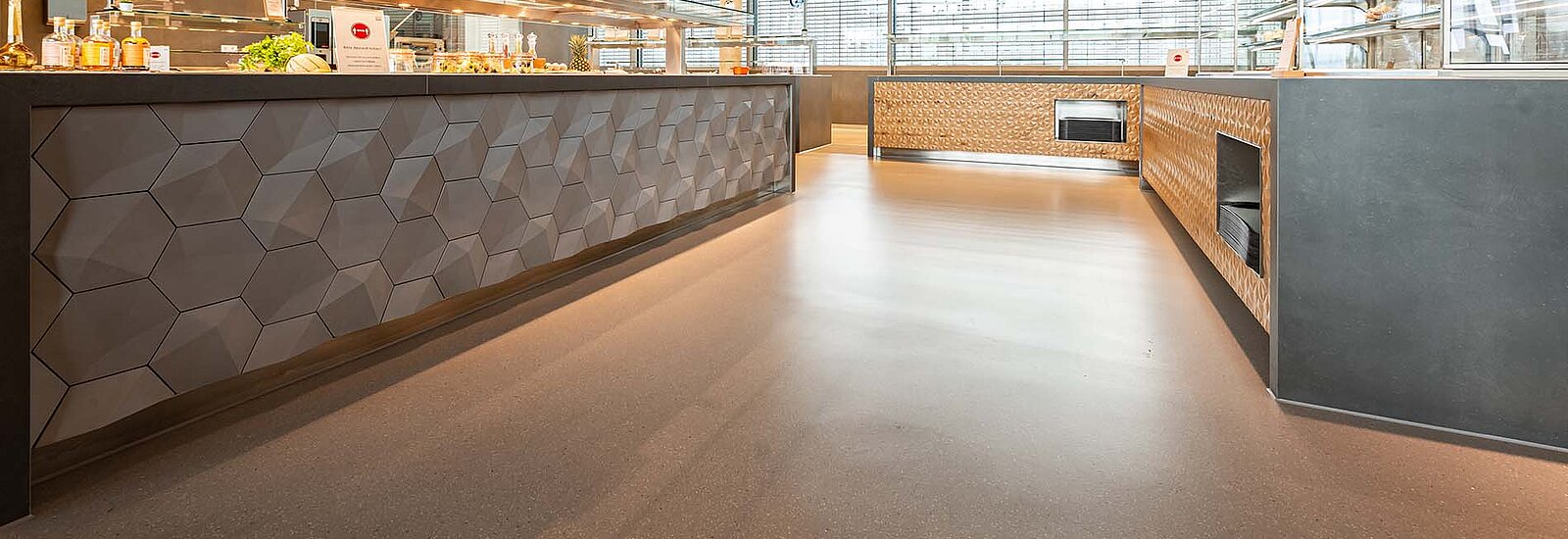

BARiT® Kunstharz-Belagstechnik GmbH installed seamless epoxy resin-bonded terrazzo coverings in various slip resistance classes of R 12 V4, R 11, R 10 and R 9 in the functional large kitchen areas. In the output and free-flow areas, the surfaces were given a modern synthetic resin-bonded design floor.

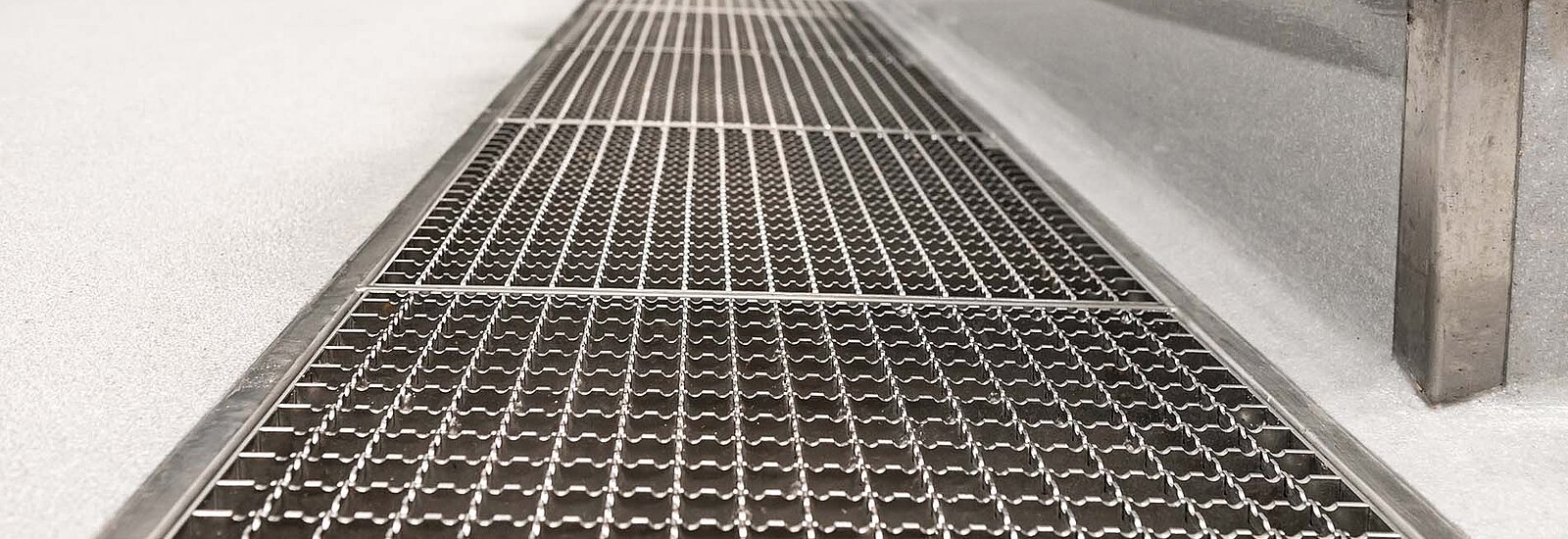

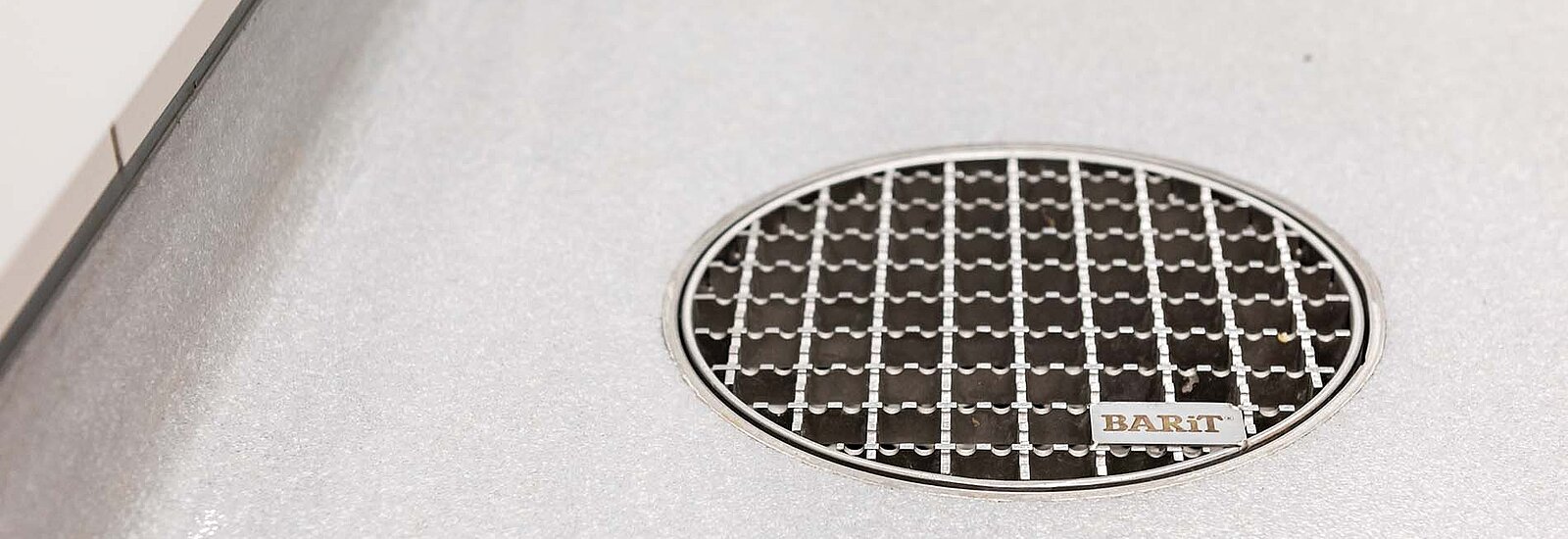

The MASTERTERRAZZO connects seamlessly to the functional areas. The employee casino is on the second floor of the 40,000 m² technology campus. With regard to the waterproofing, BARiT® installed the 550 m² floor construction for the entire large kitchen and the serving area. In order to be able to warp pipes close to the ground, a 120 mm high bonded thermal insulation fill and a low-shrinkage 90 mm thick Thermorapid screed were installed. The BARiT® drainage system comprised all box channels, slot channels and floor drains, which were delivered and sealed in a project-specific, tailor-made manner. The gutters and drains were worked seamlessly to avoid maintenance joints. The BARiT kitchen floor was built into the BARiT composite seal and thus protects the wear layer, because a waterproof seal always consists of a wear layer and a sealing layer.

To protect the structure, a seamless epoxy resin-reinforced structural seal was installed under the cooling cells. This protects against leaks under the cold room.

project description:

The architects Schmelzle und Partner from the city Dornstetten, together with the client GE Additive, decided on a seamless floor construction from Barit, as the epoxy resin-based kitchen floor underlines the client's requirements for its ultra-modern technology campus. By combining design and functionality with sustainability, this combination underlines the responsibility for health and environmental protection. The TÜV Label Premium Cert underlines through independent tests that BARiT floors are free of emissions and pollutants, the basic prerequisites for sustainable construction. It reduces environmentally harmful cleaning agents in the work areas of the industrial kitchen, but also the cleaning effort itself and thus relieves the staff.

The tele-grey MASTERTERRAZZO is repeatedly immersed in different interplay of colors through the lighting, the floor-level windows and the elements of the serving counters, so that the floor receives different color accents depending on the time of day. The grain size of the kitchen floor was adapted to the basic colors of the MASTERTERRAZZO.